Research and Innovation

We’re an innovating company placed in the Science Park Area of Trieste – Italy. Our goal is to invent, project, patent and offer specific components to users. We create modern application in the field of industrial vision. So that research and innovation are the fundamental elements of our mission, that took us to the international patent for a revolutionary system of acquisition of images through the tele-centric lens, able to reach the field of view up to a meter.

Per more information on our patent see Wide Field Telecentric Lens.

Simple solutions for complex problems

The precision and reliability of laboratory instruments in the industrial field: 3I products bring the high performance of the laboratory instruments into the industrial applications. They’re resistant, solid and compatible for integration with the structural profiles. Our optomeccanical products are perfect for simplifying the operations of assembly, regulation and integration.

Image-processing software

We offer the consulting and design of both hardware and software solutions, which is: controlling the panels for drillings, dimensions, drillings, color, quality with no contact.

The 3I vision systems’ design is based on the specific demands of client regarding both software and hardware. The optical control can take place on the assembly line as well as outside, for sample check.

For information, feasibility valuation and quotes please, contact us.

Our Systems

-

Dimensional control:

Controlling the plain elements as panels and sheets, verifying the position, depth and dimension of drillings, millings and other kinds of productions. The 3I company invented and patented a new technology able to surpass the performance of systems in use nowadays. Read more about “Wide field” telecentric lenses.

-

Quality control:

The optical quality control permits to identify lacks of production or those of the finish. In fact, it is possible to control both the coating and the painting.

-

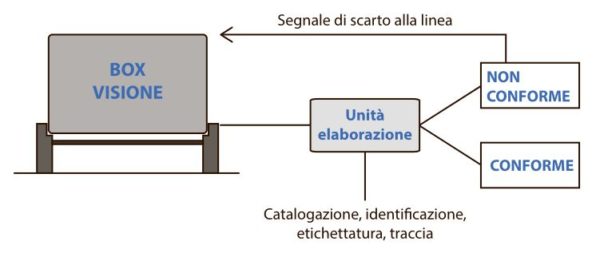

Identification systems:

These systems permit supervising and optimizing the identification of product over the bar codes or labels. It is also possible to recognize the finish based on the specific parameters, apart form managing the scraps of the lines. This way the assignment or shipping errors can be avoided.

-

Acquisition systems:

These systems permit to acquire and manage the high resolution images and the high cromatic yield. It is performed in Cloud and permits acquiring elements of huge dimensions such as marble sheets or natural elements.

-

Monitoring systems:

These systems permit monitoring of the hidden or inaccessible points of the production. So, they make it possible for the operators to work safely and they ease the control operations.